|

JDMIX J-Series Inline Static Mixers

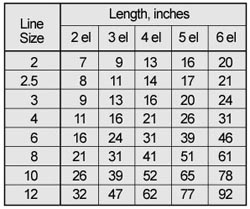

The JDMIX, Inc. “J” Series inline mixers are specifically designed for use where additives to the main pipeline flow have already been introduced upstream of the mixer. These unique inline mixers have four mixing zones between each element set. Inside each zone, the increased turbulence realized ensures that the chemical additives are dispersed throughout the circumference of the pipeline. The first section of the element redirects the flow from the top of the pipe wall, forcing it to the bottom. The second section reverses the process, forcing the flow back to the top. The same mixing action takes place from side-to-side of the pipe wall. Using between two and six mixing elements, with velocities ranging from 1 – 10 feet per second, mixing is completed. In addition, the angles of the elements can be changed to meet pressure drop restrictions in gravity feed applications, or where pump pressure is limited.

| Housing: Carbon Steel, schedule 40 Stainless Steel, schedule 40 PVC, schedule 80 Fiberglass, 150 psi rated filament wound Flanges: ANSI B 16.5 - 150 lb. Drilling Carbon Steel & Stainless Steel - RFSO PVC -3" & Above - Raised Face PVC - 3/4 - 2" - Flat Face FRP - Flat Face |

|

|

|

|

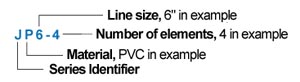

Symbol / Material S = Stainless Steel C = Carbon Steel P = PVC F = Fiberglass |

Note: Larger sizes and other materials available.

To Request a Static Mixer Quote online, click here.

Home | Products | Applications | Operation | Contact